Metal fabrication plays a vital role in our society, enabling the transformation of sheet metal into various shapes and forms. Metal fabricators employ techniques such as welding, cutting, stamping, and more to craft the essential structures and components that underpin our daily lives. Whether it’s hand railings or heavy machinery, metal fabrication is responsible for producing crucial elements of our everyday existence.

Numerous metal fabricators opt for powder coating for their projects. Powder coating involves applying a dry powder onto charged surfaces of metal fabrication projects. Upon application, it imparts a protective layer to the material, in addition to offering various other advantages. This method is gaining popularity due to its numerous benefits.

Here is a summary of why manufacturers employ powder coating in metal fabrication and how it could prove advantageous for you.

Advantages of Using Powder Coating in Metal Fabrication

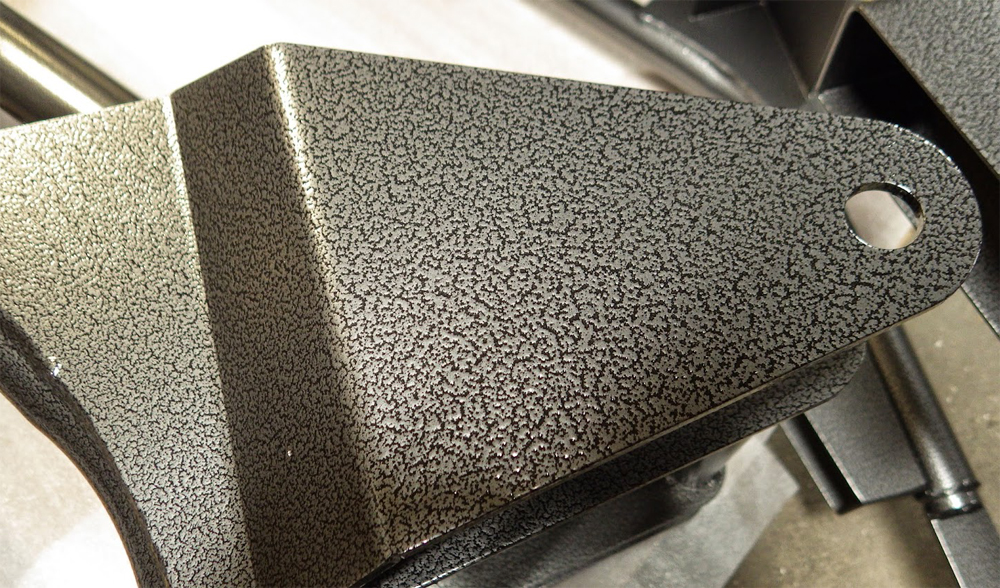

Powder coating augments the durability of metal fabrication projects by introducing an additional protective layer. After shaping the metal, fabricators apply the coating to its surface. Thanks to the charged surface, the powder adheres to it and remains securely in place after the curing process. This technique is frequently employed by manufacturers for materials such as steel, aluminum, and plastic.

Following its application, powder coating offers multiple benefits for metal fabricated structures. Due to its numerous advantages, this process is experiencing a surge in popularity.

Here are some of the benefits of the powder coating process.

Enhanced Durability

Upon applying powder coating to a structure or object, its protective qualities can endure for up to 40 years. Powder coating empowers metal to withstand the rigors of weather conditions and prolonged, continuous use. Typically, your metal material won’t necessitate any additional maintenance post-application. The electrostatic charge ensures comprehensive coverage on all exposed areas of the metal.

Metal fabricated objects are susceptible to scratches and wear in their day-to-day use. However, a powder coating provides a robust protective layer for the metal, enhancing its ability to withstand scratches and other imperfections. Consequently, your metal maintains a fresh and lustrous appearance even after years of use.

Enhanced Aesthetic

Another advantage of powder coating lies in its capacity to impart a sleek and appealing appearance to the metal. Unlike painting, it achieves a smooth finish for your metal project with just one application. Additionally, it contributes to diminishing fading effects over time. The uniform and attractive finish elevates the overall quality of your product, concealing pre-existing depressions or scratches while enhancing the overall aesthetics of your material.

Furthermore, there is a wide array of color options available for your coating. If your fabricated metal item needs to harmonize with a particular environment, you can choose the color that best complements the desired theme. For instance, if you require a hand railing to align with a specific aesthetic, powder coating can enable you to achieve the exact color you need.

Corrosion Protection

Corrosion is a universal challenge affecting all metals, representing a detrimental electrochemical process that progressively deteriorates materials. Atoms on the metal’s surface undergo oxidation, losing electrons to oxygen or water, ultimately leading to the degradation of the metal surface. One common manifestation of corrosion is the formation of rust. This process is responsible for the degradation of numerous metal projects, necessitating replacements over time.

Nonetheless, powder coatings can enhance the metal’s resistance to corrosion. By enveloping the entire surface, they impede continuous contact with air, a factor that can accelerate corrosion. As a result, the longer a material resists corrosion, the more it extends its lifespan.

Eco-Friendliness

The most prevalent alternative to powder coating is paint finishes, which can be effective but come with their drawbacks. Paint-based finishes usually contain volatile organic compounds (VOCs), which, due to their toxicity, can pose health and environmental risks. These compounds linger in the air, contributing to environmental harm and diminishing air quality, all of which can have adverse effects on people’s well-being.

In contrast, the dry powders utilized in powder coatings are free from VOCs. This renders powder coatings a significantly healthier choice for both the environment and human health. When you employ powder coatings, there is no risk of exposing anyone to toxic substances, and you won’t generate any air pollution, thus establishing powder coatings as a more environmentally friendly alternative.

Cost-Efficiency

Another advantage of powder coatings is their cost-efficiency. The entire process of applying powder coating is notably swift. Once applied, the metal becomes ready for use in a short amount of time, and it generally demands no additional maintenance after the application and curing. This rapid process translates into improved efficiency and reduced labor expenses. The quicker your process, the more cost savings you can achieve.

Furthermore, powder coatings contribute to extending the lifespan of the metal, meaning you won’t need to replace it for many years. This absence of additional replacement costs results in further monetary savings.

In summary, the substantial advantages of powder coating are compelling many metal fabricators to adopt this method for their projects.

Contact China-Static for Professional Powder Coating Machines

Powder coating offers numerous advantages in the realm of metal fabrication.

For more than 2 decades, China-Static has been providing professional powder coating machines and related accessories and spare parts to customers coming from different industries with different powder coating requirements. Furthermore, China-Static also provides professional advice for any difficulties our customers may encounter when applying power coating.

To have an upgraded powder coating equipment before your next work, simply Request a Quote from China-Static today.