If your company deals with metal products and components, you require dependable methods to reinforce their strength and reliability. For example, if you produce outdoor equipment, such as cranes or aerial platforms, you must ensure their robustness and resistance to any chemicals they come into contact with during operations. Similarly, if you manufacture metal patio furniture pieces, you want them to withstand corrosion and rust induced by weather while still having an attractive appearance that appeals to customers. In such scenarios, powder coatings present an excellent solution.

This guide provides answers to various questions regarding powder coating and its impact on metals, such as aluminum and steel. It covers topics such as how powder coating works, and whether powder-coated steel is susceptible to rusting.

An Intro of Powder Coating

Polyester-based powder coating employs uniform, dry microbeads of polyester to coat materials. The microbeads have an electrostatic charge that helps them adhere to the underlying materials. Compared to paint, powder coating provides a more robust, durable, and resilient finish. It is particularly useful for items that need to withstand extreme weather conditions or prolonged usage without compromising their quality.

The application process for powder coating is distinct from that of paint and other coatings. Unlike most coatings, which come in liquid form, powder coatings require a dry application method. Liquid paints typically contain evaporating solvents that aid in their adhesive properties.

Manufacturers usually apply dry powder electrostatically using a spray gun in powder coating, and then cure it in a curing oven or under ultraviolet light. This method imparts remarkable durability and resistance to the coating. Furthermore, the curing process allows for the application of powder coating to materials beyond conventional metals, such as carbon fiber, composites, fiberboard, and plastics.

There are generally two forms of powder coating materials:

Thermoplastics: Thermoplastics, including nylon and polyvinyl chloride (PVC), can undergo heating, molding, and curing multiple times. These materials are easy to modify after curing, and their coatings can be easily removed. They are also flexible and resistant to chemicals.

Thermosets: Thermosets, such as epoxy resins and phenolic resins, can only undergo curing once. However, after the curing process, they exhibit greater heat resistance and are better suited for high-temperature applications.

Powder Coating’s Advantages

Here are some advantages of applying powder coating on metal surfaces:

Hardness and durability: Powder coating’s curing process imparts strength and durability to the coating. As a result, the finished coating will not peel or flake.

Corrosion resistance: Powder coating acts as a barrier, safeguarding against various types of corrosion, including rust. Over time, exposure to moisture and oxygen causes natural metals like steel to rust. Powder coating creates a barrier that prevents rust formation and ensures the metal remains rust-free. Untreated aluminum does not rust, but it can oxidize and form a chalky-white substance. To protect metal parts from the elements and resulting deterioration, most outdoor-use metal parts have powder coatings.

Visual appeal: In addition to durability, powder coating imparts an attractive finish to metal surfaces. It is particularly useful for metal products designed to be visually appealing, such as patio furniture or visible building components, as it provides an elegant appearance.

Cost-effectiveness: Powder coating is also a cost-effective method compared to wet painting and other strengthening techniques. While manufacturers can create robust products with durable alloys, these alloys can be expensive. For example, stainless steel is known for its strength and corrosion resistance, but it is costly to produce and acquire. On the other hand, coating carbon steel with protective powder is a more economical solution.

Environmental responsibility: Powder coating is considered an environmentally friendly option as it contains minimal volatile organic compounds (VOCs) and does not include heavy metals such as chrome.

Powder Coated Steel

Powder-coated steel offers a combination of inherent strength and longevity with the added benefit of resistance to various types of corrosion due to the protective coating. It is a popular choice for a wide range of applications, such as outdoor and indoor furniture frames, metal canopy frames, metallic roofs, windows and doors, scaffolding, cranes, and trailers. With its durability and resistance to corrosion, powder-coated steel is an ideal material for products that require strength and long-lasting performance.

Can powder-coated steel resist rust? In general, yes. Powder-coated steel is highly resistant to rust, which means it is unlikely to develop unsightly rust patches or leave red streaks on outdoor furniture or building facades. However, if the coating sustains damage, such as scratches or chips, moisture can enter and promote rust formation. While powder-coated steel is not entirely rustproof, it remains a strong and durable material that offers significant protection against corrosion.

Some advantages of using powder-coated steel are:

Strength: Powder-coated steel is known for its exceptional strength, making it a reliable choice for various applications, including architectural designs and furniture. Its robustness provides security and instills confidence in users.

Longevity: Powder-coated steel is known for its exceptional durability. The powder coating forms a tight seal that prevents contaminants from penetrating the steel, resulting in a longer lifespan for the material.

Thick, consistent finish: Powder coating ensures a more consistent and even finish compared to traditional paint application, which may result in clumping or uneven thickness, providing better and more uniform protection.

Aesthetic appeal: Powder-coated steel products offer both functionality and aesthetics. Unlike untreated steel, powder-coated steel can have a polished appearance and be customized with a variety of finishes in different colors and styles, making it a versatile option to complement any building’s décor.

Corrosion resistance: Powder-coated steel, like other powder-coated metals, has excellent corrosion resistance due to its coating that forms an impermeable barrier to prevent moisture and other contaminants from entering, preventing corrosion from developing on the metal. This means a lot for vehicle items like rims that are exposed to outdoor environment for most of the time.

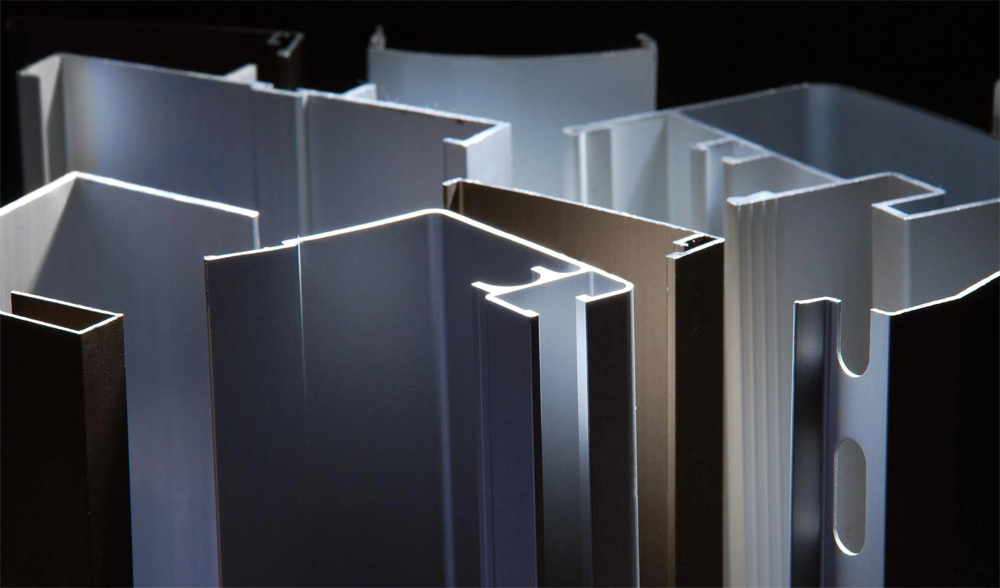

Powder Coated Aluminum

Powder-coated aluminum combines the lightweight nature of aluminum with the durability and resistance of powder coating. It is easy to transport and withstands harsh weather conditions without corroding, making it ideal for use in products like metal patio furniture, metal railings, doorknobs, door frames, and window frames.

Here are some advantages of utilizing powder-coated aluminum:

Lightness: Powder-coated aluminum is lightweight and highly portable, making it easy to move around. This makes it an ideal choice for applications such as furniture rearrangements and product shipments, as it provides an efficient and effortless solution.

Durability: Powder-coated aluminum is not only lightweight but also durable, with the powder coating providing an extra layer of protection against corrosion and wear. This makes it an excellent choice for outdoor furniture, railings, and other products that need to withstand harsh weather conditions and constant use.

Elegance: Powder-coated aluminum not only offers strength and durability, but also an attractive appearance. With a range of colors and stylish designs available, powder-coated aluminum products are often sought-after for use as furniture or decorative items.

Corrosion resistance: Powder-coated aluminum offers excellent resistance to corrosion, which makes it a popular choice for outdoor applications. The powder coating forms a barrier that protects the metal from moisture, chemicals, and other contaminants that can cause corrosion. This ensures that the aluminum remains in good condition for a long time, even when exposed to harsh environmental conditions.

Purchase High Quality Powder Coating Machines from China-Static

If you want to experience the advantages of using corrosion-resistant materials in your operations, China-Static can help you with our finishing equipment. Our powder coating machines allow you to provide durable and dependable coatings that enhance your products’ quality and longevity. We provide a range of options to cater to your specific finishing requirements.