Selecting the ideal powder coating color can be a time-consuming process given the multitude of options available. Yet, by keeping essential factors in mind, you can streamline your search and discover the perfect color. Explore your powder coating color choices and gain insights into the key considerations for selecting the ideal shade to meet your specific needs.

How Many Colors Can Be Obtained in Powder Coat?

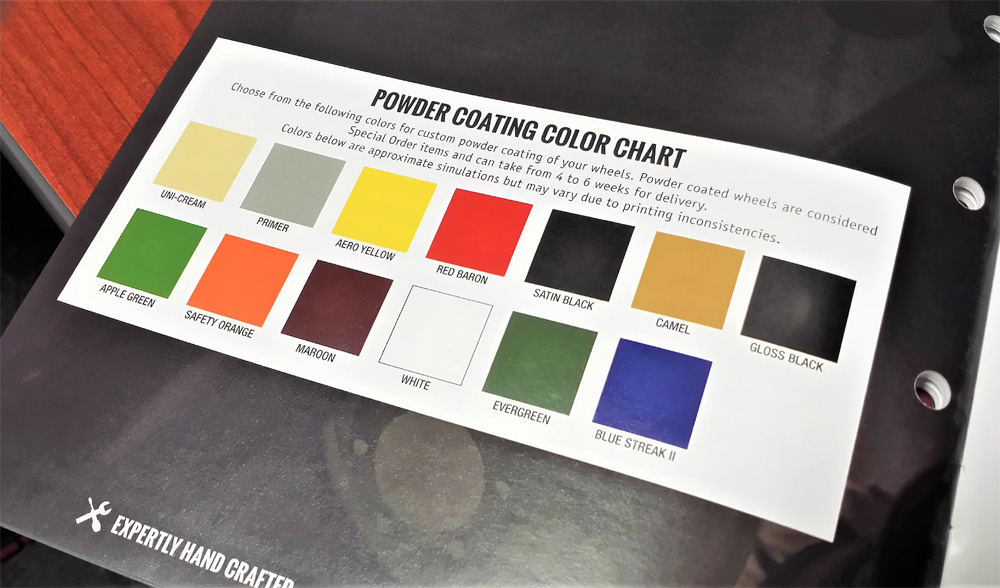

Is it possible to obtain any color with powder coating? Absolutely! Virtually, the spectrum of colors is at your disposal. You can choose from a broad range of timeless hues like white, black, silver, beige, brown, and gray for a more neutral appearance. Additionally, if you desire a vibrant and lively look, an array of cheerful colors, including various shades of yellow, red, blue, green, purple, and more, is readily accessible.

The variety of powder coat colors appears almost limitless. Nevertheless, it’s essential to acknowledge that certain distinctive colors might not be readily accessible. Some shades may necessitate a customized powder coating order. While you can still attain your desired aesthetic, it’s worth noting that your project’s completion time may be longer compared to projects using readily available, in-stock color options.

Color matching services are also provided. Whether you require a touch-up or are extending previous work, color matching ensures a cohesive and uniform design.

What to Consider When Choosing a Powder Coating Color

Selecting a powder coating color involves more factors than meets the eye. Beyond simply choosing a color or requesting a custom shade, several other considerations come into play. These include the color’s gloss and texture, durability, intended product use, the possibility of incorporating special effects, and the impact of lighting.

These factors can have a significant influence on the ultimate color and design of your powder coating, potentially leading you to opt for a different color than your initial choice.

Gloss

Gloss levels serve as an indicator of the final product’s shine and reflectivity. When selecting a color, gloss becomes a vital aspect to contemplate because varying gloss levels can subtly alter the color’s overall appearance.

Certain gloss choices, like matte, have the potential to slightly mellow or subdue the color. Therefore, it’s essential to contemplate how your powder coating color will be affected when a gloss is introduced. Gloss levels span from 5 to 90. A higher gloss level results in a more radiant and glossy appearance for the product.

The typical gloss classifications encompass:

- Matte: Matte gloss, also referred to as flat, has a low light reflectivity, which can impart a subdued quality to your powder coating color. Matte finishes are particularly suitable for concealing surface imperfections. Nonetheless, they tend to be more challenging to clean compared to alternative options.

- Gloss: Positioned between matte and high gloss, a standard gloss choice strikes a balance, offering a pleasant level of reflection without excessive shine. It’s more manageable to clean than matte finishes and entails lower surface friction as well.

- High gloss: High gloss is exceptionally reflective and exhibits a striking shine. With its exceptionally smooth surface, materials coated with high gloss are effortless to clean, rendering them well-suited for applications in the medical and food processing sectors. However, it’s important to note that high gloss accentuates any surface imperfections, necessitating an impeccably even and well-finished material for optimal results.

Texture

The texture of your powder coating selection significantly influences the ultimate design and appearance of the coated surface. Among the most favored texture options are:

- Wrinkled: This texture exhibits minimal shine and offers a gritty, sandpaper-like feel. Such a powder coat texture boasts exceptional durability, rendering it an excellent choice for industrial environments. It can endure daily wear and tear, resisting scratches effectively, while also providing remarkable corrosion and weathering resistance.

- Hammer-tone: Hammer-tone textures replicate the surface of an orange peel or the exterior of a golf ball. They are particularly well-suited for outdoor furniture, architectural uses, and lighting fixtures, thanks to their contemporary aesthetic. Additionally, this coating excels in withstanding minor scratches or impacts.

- River vein: River vein textures demand the expertise of a seasoned professional for proper application. Characterized by small, river-like channels that traverse the material, this texture is well-suited for two-tone designs, although single-color options are also offered. This coating imparts a distinctive appearance and is suitable for a variety of indoor and outdoor applications.

Special Effects

Certain powder coating service providers may extend their offerings to include supplementary powder coating effects. For instance, metallic effects introduce variability in color perception depending on the viewer’s perspective. As you change your vantage point, the color will undergo shifts and alterations, resulting in a distinct and dynamic color effect.

Translucent effects may also be on the menu. With this choice, the underlying metal remains visible beneath the powder coating. Translucent coatings extend beyond clear or neutral colors, encompassing a spectrum of options including blues, reds, and various other hues.

It’s important to bear in mind that these distinctive effects may not be consistently accessible. The availability of unique and special offerings will differ from one provider to another.

Durability and Product Purpose of the Product

When deciding on a powder coating color, it’s crucial to take into account the intended purpose of the coating. Will this coating be situated in a high-traffic area prone to accumulating dirt? In such scenarios, opting for darker colors with a glossy, resilient, and scratch-resistant finish may prove to be the optimal choice. Conversely, if you plan to powder coat something primarily for decorative purposes rather than functional use, concerns about cleaning upkeep and scratch resistance may take a back seat.

At a minimum, keeping the product’s intended purpose in mind can assist in streamlining your choices. If you’re powder coating an item that requires visibility and prominence, it’s advisable to steer clear of neutral tones or colors that might blend into the background. Instead, opt for vibrant hues like bright yellow or red to ensure it stands out conspicuously.

Lighting

Colors can exhibit slight variations depending on the lighting conditions. What you perceive online or in a store may appear differently in your actual setting, especially if you have exceptionally bright or dim lighting. If feasible, consider bringing a swatch to the precise location where you intend to apply the powder coating to gauge how your chosen color responds to the lighting. At the very least, factor in the lighting situation when making your color selection.

Count on Powder Coating Machines and Service from China-Static

Since 2010, China-Static has been providing first-class Powder Coating Machines and services for different industries. We have top ranking and affordable powder coating machines, an experienced technical team and comprehensive start-to-finish capabilities. We are ready to meet all your powder coating requirements at any time.

Our team will accompany you throughout your work cycle. With our excellent products and professional team service, you can rest assured that your project is entrusted to capable hands.

Contact Us today for more information about our products and our services and how China-Static can enhance your business.