HN-310 Electrostatic Powder Coating Machine

Technology Service Responsibility

HN-310 Electrostatic Powder Coating Machine

One Shot to Conquer Any Coating Barriers

Imported Components to Achieve Classic High Quality

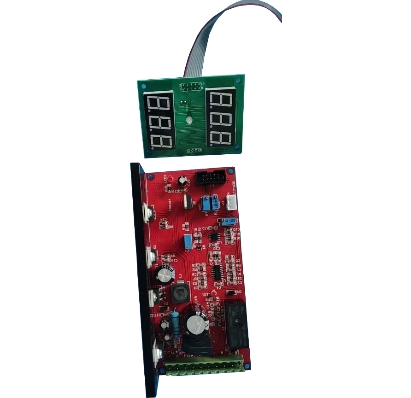

Digital display of voltage and current for easy identification; stable central electrode operation for high coating efficiency; automatic adjustment of voltage and current according to the distance between the gun and the surface; more intelligent and more convenient.

Innovative and Efficient Electrostatic Coating Gun

Innovative core technology for high safety and high coating efficiency; ergonomic design for saving materials and for long service life.

Large Powder Volume and Venturi Coating Pump

Body of the pump and the copper nozzles are made of special metal materials for high tightness and wear-resistance; coating pump with large powder volume; advanced venturi technology to achieve more uniform coating effect.

High Quality Oil Water Separator

The oil water separator can filter the excessive water, oil and clean the gas in the compressor (aka. air pump).

Features and Advantages

The machine is manufactured by imported components and through advanced technology. It has current and voltage customization function, as well as adaptive coating modes for flat workpieces, groove workpieces and workpiece recoating mode. Its coating effect is at the leading level compared with similar machines from abroad.

Current and Voltage Customization

The current and voltage of the electrostatic can be arbitrarily customized by pressing “+” and “-” keys. Its current range is 15-100 μA, while the voltage range is 15-100 kV. It can also satisfy the customized coating demands from customers.

Flat Workpiece Coating Mode

The machine adopts circular nozzles with highly efficient powder transmission performance so as to enhance the wrap-around of powder. This mode is suitable for the coating for workpieces in different shapes.

Technical Parameters | ||

Aerodynamic Parameters | Input Air Pressure | 0-8 bar |

Output Pressure | 0-6 bar | |

Control Voltage of Solenoid Valve | DC 24 V | |

Electric Parameters | Input Voltage | AC 100-240 V |

Power Supply Voltage | DC 20 V | |

Output Voltage | DC 0-20 V | |

Output High Voltage | DC 100 kV | |

Output Current | 0-100 μA | |

Output Frequency | 30 kHz | |

High Voltage Installation Mode | Built-in | |

Groove Workpiece Coating Mode

The machine adopts fan-shape nozzles, which can achieve an excellent coating effect on flat surfaces as well as sunken places. And Faraday Cage phenomenon can be effectively overcome. With its great penetrating capacity, it can be used to coat complex workpieces and reduce operating costs.

Workpiece Recoating Mode

The machine adopts circular or fan-shaped nozzles, which can realize high quality and ultra thick coating of the workpiece. This recoating mode can ensure the uniform and smooth surface of the recoated workpiece and the elimination of the orange peel phenomenon. It is adaptive for the coating of the workpieces with low electrical conductivity.

Advantages of Electrostatic Powder Coating

- Paint materials used in powder coating can be either powdered or liquid.

- A variety of colors and finishes will be available in powder coating. Powder coating can be applied to metallic, high and low gloss and clear finishes. Compared with liquid coating, color matching in powder coating can be a little bit more difficult than liquid coating. But a high quality coating in the correct color can easily be ensured by an experienced powder coating specialist.

- The quality of powder coating can be maintained for many years, keeping the color sharp and vivid for long period of time without fading.

- Powder coated items generally have fewer appearance differences than liquid coated items between horizontally coated surfaces and vertically coated surfaces.

- Powder coatings can produce much thicker coatings than conventional liquid coatings without running or sagging.

- The painted powder coatings adheres extremely well to the grounded objects as the most durable finish available. Several compounds of can be added to the powder coatings to enhance anti-corrosive and anti-abrasive properties, maintaining the quality of the coating for a longer period.

- A wide range of specialty effects can be easily achieved using powder coatings that would be impossible to achieve with other coating processes.

- Curing time is significantly faster with powder coatings compared to liquid coatings especially when using ultraviolet cured powder coatings or advanced low bake thermosetting powders.

- Around 98% of the overspray can be collected for reuse for its better wrap-around.

- When solvent-based coatings is applied, volatile and toxic compounds (VOC) will be emitted into the air and pollute the atmosphere. It will be toxic both to the improperly protected workers and the environment. Thus, extensive air treatment and exhaust systems will be required to clear the air. Powder coatings contain no solvents and release negligible amount of VOC into the atmosphere. Therefore, there is no need to be concerned about the transportation and handling of solvents, as well as the purchase of the costly pollution control equipment. Companies can comply with the regulations of the US Environmental Protection Agency more easily and economically.

- Working time and labor force can be reduced since there is no need for undercoat in advance before the process.

- Using powder coating requires very little training. This is a cost-effective option especially when the quality and durability of the product are considered.