Electrostatic Powder Coating Gun

Technology Service Responsibility

Electrostatic Powder Coating Gun

Product Advantages

- The combination of coating gun, powder pump and controller achieves high powder extraction rate and improves powder application efficiency. The new powder pump adopts the latest technology to obtain more powder while reducing the flow rate. Makes the powder output more uniform, Softer. This increases the powdering rate and overcomes areas that are difficult to spray.

- Compact structure, superior balance and feel, reduce operator fatigue and improve spraying quality.

- The new lighting function has effectively reduced the scrap rate of the product.

Pretreatment For Powder Coating

To achieve the best results with your powder coating process, your product needs to be clean—free of dust, debris, oil, rust, old paint or finish material. Anything left on your product prior to coating will affect the powder’s adhesion and durability. That’s where pretreatment comes in.

Pretreatment equipment is used before your product is ever powder coated and is designed to make sure that your product is as clean as possible before powder is applied.

Powder coating application is almost always done with a special Powder Spray Gun. In order for powder coating to work effectively, the powder must be electrostatically charged. The only way to apply this charge is with a spray gun designed exclusively for powder coating. Compressed air moves powder through the gun from a hopper or directly from the box the powder is stored in. The compressed air blows powder out of the gun as a tightly formed cloud. As the powder leaves the gun, it receives an electrostatic charge. Once charged, the powder cloud envelopes the part and the powder sticks to the surface of the grounded part (which is one of the reasons why powder coating equipment is so easy for new operators to use).

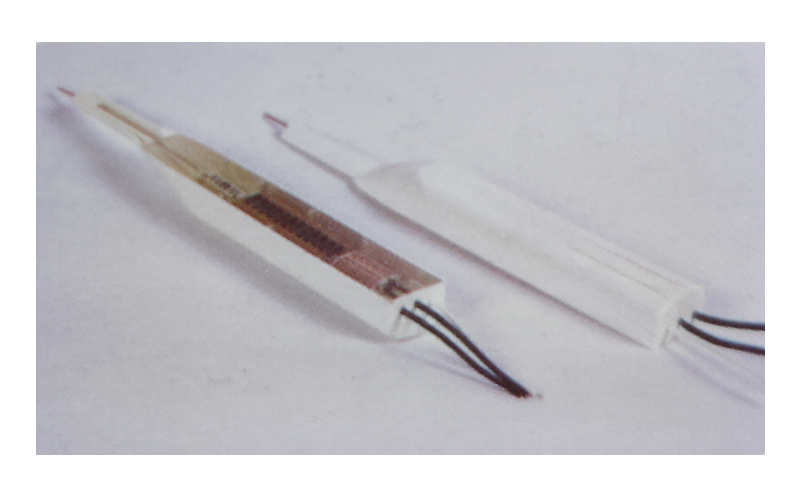

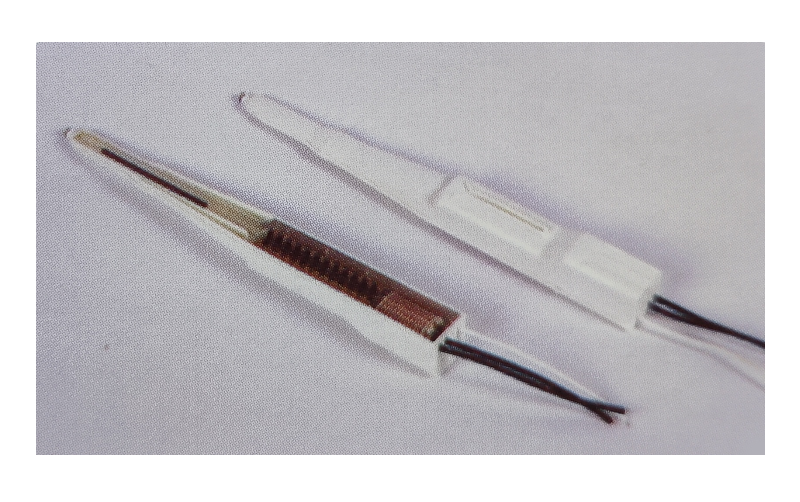

High Voltage Transformer for Electrostatic Powder Coating Gun