Electrophoretic deposition (also referred to as electrocoating or e-coating) and powder coating are two comparable industrial metal finishing processes. Both methods involve the application of a coating onto a substrate to achieve various objectives, including improving corrosion protection, increasing wear resistance, and promoting adhesion.

When deciding which coating is optimal for your manufacturing operation, it’s essential to consider the significant benefits of e-coating over powder coating. In this regard, let’s delve deeper into the characteristics of both e-coating and powder coating.

E-Coating

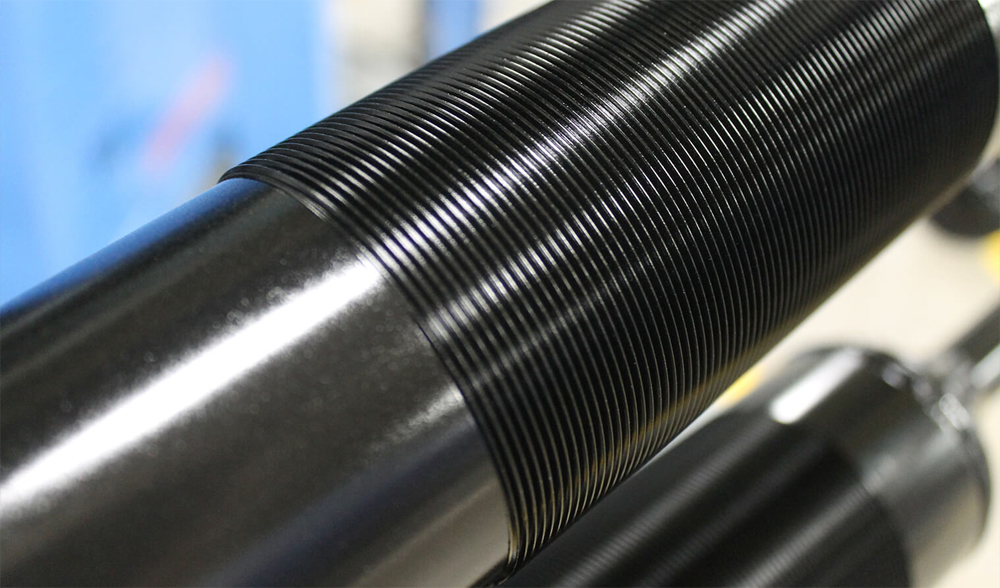

In comparison to powder coating, e-coating has a closer resemblance to electroplating. During the e-coating process, the substrate is submerged in a bath containing water-based solutions such as paint or epoxy. Electric current is applied to draw suspended particles from the solution and onto the surface of the substrate. The thickness of the coating is controlled by adjusting the voltage level and electrodeposition is carried out until the desired thickness is attained. Subsequently, the coated substrate is cured in an oven to encourage cross-linking.

Powder Coating

Although e-coating is known as a “wet” process, powder coating is different in that it uses a dry powder made up of specific epoxy resins and curing agents. The powder is applied to the substrate’s surface using an electrostatic spray gun, where the electrically charged particles stick to the surface. The final step in the powder coating process is curing, which involves melting the particles and catalyzing a chemical reaction that results in the desired finish.

When Can E-Coating be a Logical Choice

Due to the way e-coating is applied, it is often a superior choice for coating parts that have inaccessible areas. Immersing an object in a liquid results in a more uniform and comprehensive distribution of the coating than is typically achievable with a spray gun. In comparison, the powder coating process tends to create a thicker coating.

On the other hand, the e-coating process offers the advantage of greater control over the thickness level, making it easier to achieve a thinner coating compared to powder coating. This is especially significant in the automotive industry, where e-coating is commonly used as a primer coat to enhance protection against corrosion before painting.

Apply Powder Coating on Top of E-Coating

Certainly. Applying a powder coating topcoat on top of an e-coat film is not a novel technique. It has been effectively utilized in various industries for many applications. The powder and e-coats can bond well without any issues, provided that the e-coat is appropriately cured for the right duration.

Your metal products can experience exceptional benefits when powder coating is applied over e-coating, including:

Durability: If you incorporate inner e-coating into your powder-coated items, you can increase their longevity and resilience against challenging environmental conditions. E-coating is widely recognized for its remarkable durability, effectively withstanding outdoor elements and indoor factors such as household chemicals. Its superior performance has resulted in a growing demand for it as an additional layer in powder-coated applications.

Coverage: When it comes to reaching difficult-to-access areas within your metal products, E-coating is the superior option compared to powder coating. Nevertheless, if you desire a decorative touch, you may consider adding powder coating. For a comprehensive coverage and an attractive finish, you can opt for a process where your product is first e-coated, cured, and then powder coated.

Corrosion and UV Protection: E-coats are renowned for their exceptional ability to resist corrosion, making them a popular choice for industrial applications. However, as most e-coats are not UV stable, they are typically used as either primers or finishes. To guarantee protection against both corrosion and UV rays, it’s recommended to combine e-coating with a layer of UV-resistant powder coating. This ensures that the superior corrosion protection provided by e-coats is paired with the UV protection offered by powder coating.