When it comes to metal finishing, there is a wide range of methods to choose from. The objective is to improve the material’s durability, aesthetic appeal, and resistance to rust. Among the various approaches, anodizing and powder coating are particularly prominent in the industry. While each method has its merits, powder coating often emerges as the superior choice. This comprehensive article delves into the intricacies of these two finishing techniques, examining their processes, advantages, disadvantages, and the reasons why powder coating frequently surpasses its counterpart.

Benefits of Anodizing

Anodizing is a finishing technique primarily utilized for the protection of aluminum. Its scientific process involves an electrochemical procedure that transforms the metal surface into a robust and corrosion-resistant anodic oxide coating. This oxide layer becomes an integral part of the underlying aluminum, creating a strong bond that effectively prevents peeling.

Anodizing’s appeal lies in its ability to enhance the natural luster of metal, ensuring a smooth and visually pleasing finish while simultaneously providing durability against wear and tear. Additionally, anodizing offers the advantage of producing a diverse range of colors. Beyond its aesthetic qualities, this process also delivers practical benefits such as electrical insulation and improved adhesion for glues and paints.

Nevertheless, anodizing does come with its limitations. Firstly, it tends to be a costlier process compared to other finishing methods. Secondly, it is applicable only to certain metals. Furthermore, while anodizing effectively protects the underlying metal, it is important to note that if the anodized finish gets scratched and exposes the metal underneath, there is a risk of corrosion or rusting.

Benefits of Powder Coating

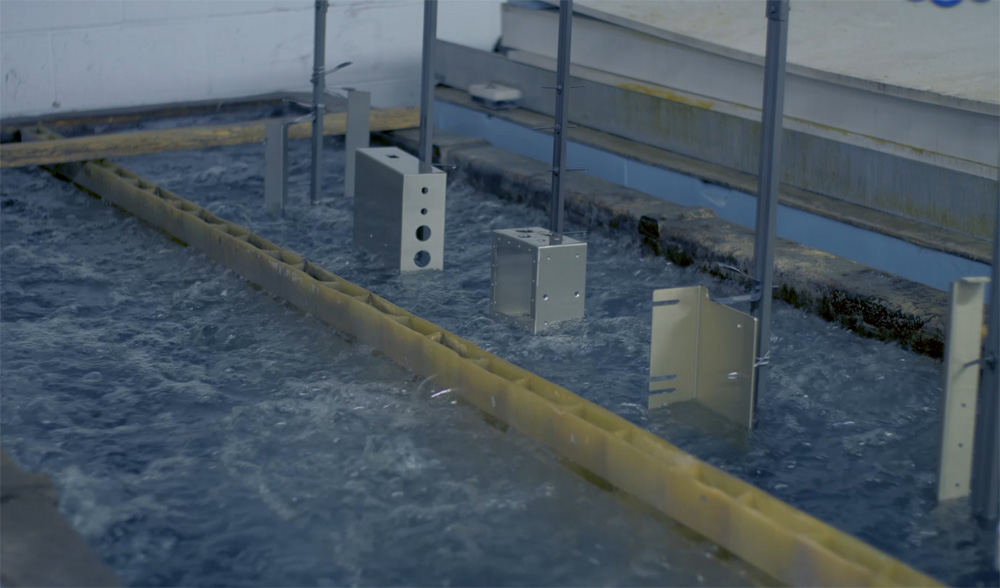

On the flip side, we have powder coating as an alternative method. This approach entails the application of a dry powder onto a metal surface, followed by heating or curing the coated metal in an oven. The application of heat causes the powder to melt and form a smooth and robust layer, creating a durable protective coating for the underlying metal.

Powder coating presents numerous notable advantages that often position it as the preferred option. Firstly, its unparalleled versatility sets it apart. Unlike anodizing, powder coating can be applied to a wide variety of metals beyond just aluminum. Secondly, it offers an impressive assortment of colors and finishes. Whether one desires a high-gloss finish, a matte appearance, a smooth texture, or a textured surface, powder coating provides nearly limitless possibilities.

Furthermore, powder coating boasts exceptional durability and corrosion resistance, guaranteeing that your end product can endure exposure to the elements and withstand daily usage. The application process allows for precise control over the thickness of the coating, resulting in a uniform finish devoid of any drips or application marks that may be left behind by alternative methods.

An important advantage of powder coating lies in its environmental impact. Unlike many other finishing processes, powder coating does not emit volatile organic compounds (VOCs) into the atmosphere. VOCs can have detrimental effects on the environment and pose health risks to industry workers, making the absence of VOCs a significant benefit. Additionally, the powder that remains unused or is oversprayed can be recycled, resulting in virtually zero waste.

The Reason Why Powder Coating Stands Out

When comparing the advantages and disadvantages of anodizing and powder coating, powder coating frequently proves to be the superior choice. It excels in terms of versatility, allowing for a wider range of materials and finish options. Moreover, powder coating checks off essential factors such as environmental friendliness, worker safety, and cost-effectiveness, further solidifying its position as the preferred option.

While anodizing can deliver an attractive and long-lasting finish for aluminum, its applicability is somewhat restricted when compared to powder coating. When working with metals other than aluminum or when aiming for a specific aesthetic outcome, powder coating generally emerges as the superior choice. It offers greater flexibility and versatility, making it the preferred option for such projects.

Choose for Your Project

When it comes to choosing the ideal finish for your metal project, the argument in favor of powder coating is strong. Its versatility spans across various metal types and encompasses a wide array of finishes. Moreover, the significant advantages of cost-effectiveness, environmental friendliness, and worker safety further establish it as the superior choice for numerous projects.

Selecting the appropriate finish can have a significant impact on the outcome of your metal project. Although anodizing has its merits, the numerous advantages associated with powder coating often position it as a superior choice.